Assessment of Rotating Machinery Condition On-Site

Rotating machinery is integral to numerous industries, including manufacturing, power generation, oil and gas, and transportation. Maintaining the reliability and efficiency of this machinery is crucial for optimal operational performance. An effective condition assessment of rotating machinery on-site allows for early detection of potential failures, reducing downtime and maintenance costs. This comprehensive guide explores the methodologies, techniques, and best practices for assessing the condition of rotating machinery in the field.

- Introduction to Rotating Machinery

1.1 Definition and Importance

Rotating machinery encompasses various equipment that converts energy into motion. Common examples include:

- Motors: Provide mechanical power to drive various systems.

- Pumps: Move fluids through systems.

- Compressors: Increase the pressure of gases.

- Turbines: Convert fluid energy into mechanical energy.

The reliability of these machines is paramount; failures can lead to significant operational disruptions, safety hazards, and financial losses.

1.2 Objectives of Condition Assessment

The primary goals of condition assessment are to:

- Identify existing issues and potential failure modes.

- Monitor the performance and health of equipment.

- Plan maintenance activities effectively.

- Extend the life of machinery and improve operational efficiency.

- Key Concepts in Condition Assessment

2.1 Condition Monitoring vs. Condition Assessment

- Condition Monitoring: Involves continuously or periodically measuring various parameters of machinery to track its health.

- Condition Assessment: A more comprehensive evaluation that involves analyzing monitored data, performing physical inspections, and interpreting results to determine the overall condition of machinery.

2.2 Types of Deterioration

Rotating machinery can experience various types of deterioration, including:

- Mechanical Wear: Resulting from friction and contact between moving parts.

- Fatigue Failure: Caused by repeated loading and unloading cycles, leading to cracks.

- Corrosion: Chemical reactions that degrade materials, particularly in harsh environments.

- Misalignment: Occurs when components are not properly aligned, leading to increased wear.

- Methodologies for Condition Assessment

3.1 Visual Inspection

Visual inspection is the first step in assessing the condition of rotating machinery. It involves examining components for signs of wear, damage, or improper operation.

Key Aspects to Examine:

- Physical Damage: Cracks, dents, or deformations in housing and components.

- Lubrication: Checking for adequate lubrication levels and identifying leaks or contamination.

- Alignment: Inspecting the alignment of shafts and couplings.

- Cleanliness: Ensuring that components are free from debris, dust, and contaminants.

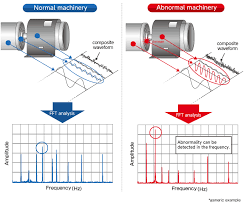

3.2 Vibration Analysis

Vibration analysis is a widely used condition monitoring technique that measures the vibrations produced by rotating machinery.

Importance of Vibration Analysis:

- Identifies Imbalances: Detects mass imbalance in rotating parts, which can lead to excessive vibration.

- Detects Misalignment: Misalignment can cause vibrations that indicate an issue.

- Predicts Bearing Failures: Specific vibration patterns can signify impending bearing failures.

Techniques Used:

- Time-Domain Analysis: Measures vibrations in the time domain to identify abnormalities.

- Frequency-Domain Analysis: Analyzes vibration frequencies to pinpoint specific problems.

- Orbit Analysis: Visualizes the motion of rotating parts in a two-dimensional plane.

3.3 Thermography

Thermography uses infrared cameras to measure surface temperatures of machinery components, helping to identify overheating issues.

Applications:

- Detects Hot Spots: Areas of excessive heat can indicate friction, electrical issues, or poor lubrication.

- Monitors Insulation Conditions: Ensures that electrical components are operating within safe temperature ranges.

- Identifies Blockages: In systems such as pumps, blocked lines can lead to abnormal temperature readings.

3.4 Ultrasonic Testing

Ultrasonic testing involves using high-frequency sound waves to detect issues such as leaks, corrosion, and material defects.

Key Applications:

- Leak Detection: Identifying leaks in compressed air and gas systems.

- Thickness Measurements: Assessing material thickness to detect corrosion or erosion.

- Condition Monitoring: Monitoring bearings and gears for signs of deterioration.

3.5 Oil Analysis

Oil analysis involves testing lubricants for contaminants and wear particles, providing insights into the condition of machinery.

Key Indicators:

- Wear Metals: Identifying metals in the oil that indicate wear in components.

- Contaminants: Detecting dirt, water, or other contaminants that can affect lubrication.

- Viscosity: Measuring the oil’s viscosity to ensure it is within operational specifications.

3.6 Performance Testing

Performance testing involves evaluating the machinery’s output and efficiency under normal operating conditions.

Parameters to Measure:

- Flow Rates: For pumps and compressors, ensuring they meet design specifications.

- Power Consumption: Monitoring electrical consumption to identify inefficiencies.

- Operational Temperatures: Ensuring machinery operates within designated temperature ranges.

- Best Practices for On-Site Condition Assessment

4.1 Establishing a Condition Monitoring Program

A structured condition monitoring program is essential for effective machinery assessment. Key steps include:

- Define Objectives: Establish clear goals for the condition assessment program.

- Select Appropriate Techniques: Choose the right monitoring techniques based on the type of machinery and specific conditions.

- Develop a Schedule: Create a routine inspection and monitoring schedule to ensure consistent data collection.

4.2 Training Personnel

Proper training is crucial for effective condition assessment. Personnel should be trained in:

- Inspection Techniques: Understanding how to perform visual inspections and use monitoring equipment.

- Data Interpretation: Analyzing collected data and identifying trends or anomalies.

- Safety Protocols: Ensuring safe practices during inspections and maintenance activities.

4.3 Documentation and Record-Keeping

Maintaining thorough documentation is vital for tracking machinery conditions over time. Key aspects include:

- Inspection Records: Documenting findings from visual inspections and monitoring activities.

- Maintenance Logs: Keeping detailed records of maintenance activities and repairs.

- Performance Metrics: Tracking key performance indicators (KPIs) to evaluate machinery effectiveness.

4.4 Continuous Improvement

Condition assessment should be an iterative process. Organizations should regularly review and improve their assessment methodologies by:

- Analyzing Data Trends: Identifying patterns and adjusting maintenance strategies accordingly.

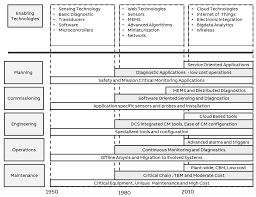

- Integrating New Technologies: Adopting emerging technologies for more effective monitoring.

- Soliciting Feedback: Engaging personnel in discussions about assessment practices and areas for improvement.

- Advanced Techniques in Condition Assessment

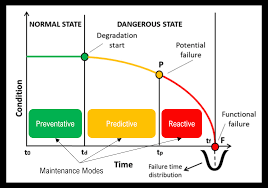

5.1 Predictive Maintenance

Predictive maintenance leverages data analysis and condition monitoring to predict when maintenance should be performed, allowing for maintenance to be scheduled just before failure is likely to occur.

Key Technologies:

- IoT Sensors: Internet of Things (IoT) devices collect real-time data on equipment performance.

- Machine Learning Algorithms: Analyze historical data to predict future failures and optimize maintenance schedules.

5.2 Data Analytics

Data analytics involves using statistical tools to analyze large datasets generated by machinery, enabling more informed decision-making.

Techniques Used:

- Root Cause Analysis (RCA): Investigating the underlying causes of machinery failures to prevent recurrence.

- Failure Mode and Effects Analysis (FMEA): Identifying potential failure modes and their impact on operations.

- Case Studies in Condition Assessment

6.1 Case Study: Power Generation Facility

A power generation facility implemented a comprehensive condition assessment program for its turbines. The program included vibration analysis, thermography, and oil analysis. By monitoring performance and identifying early signs of wear, the facility reduced unplanned downtime by 40% and extended the lifespan of critical components.

6.2 Case Study: Manufacturing Plant

In a manufacturing plant, the maintenance team adopted a predictive maintenance strategy using IoT sensors to monitor key parameters of rotating machinery. The analysis of vibration and temperature data led to timely interventions that reduced maintenance costs by 30% and improved overall equipment effectiveness.

- Challenges in On-Site Condition Assessment

7.1 Environmental Factors

On-site assessments may be affected by environmental conditions such as temperature, humidity, and dust, which can influence the accuracy of measurements.

7.2 Resource Constraints

Limited resources, including personnel, budget, and time, can hinder effective condition assessments. Prioritizing equipment based on criticality can help mitigate this issue.

7.3 Complexity of Machinery Systems

The intricacy of modern machinery systems can make it difficult to identify specific problems, requiring advanced diagnostic techniques and expertise.

- Conclusion

Assessing the condition of rotating machinery on-site is a vital process that can significantly impact operational efficiency and reliability. By employing a combination of visual inspections, vibration analysis, thermography, ultrasonic testing, oil analysis, and performance testing, organizations can identify issues early, reduce downtime, and extend the life of their machinery.

Establishing a structured condition monitoring program, training personnel, maintaining thorough documentation, and embracing continuous improvement are key practices that enhance the effectiveness of condition assessments. As technology continues to evolve, the integration of predictive maintenance and advanced data analytics will further refine the assessment process, enabling organizations to operate more efficiently and effectively.